- Home

- News

- Industry News

- Reinforced Graphite Gaskets in High-Pressure Environments

Reinforced Graphite Gaskets in High-Pressure Environments

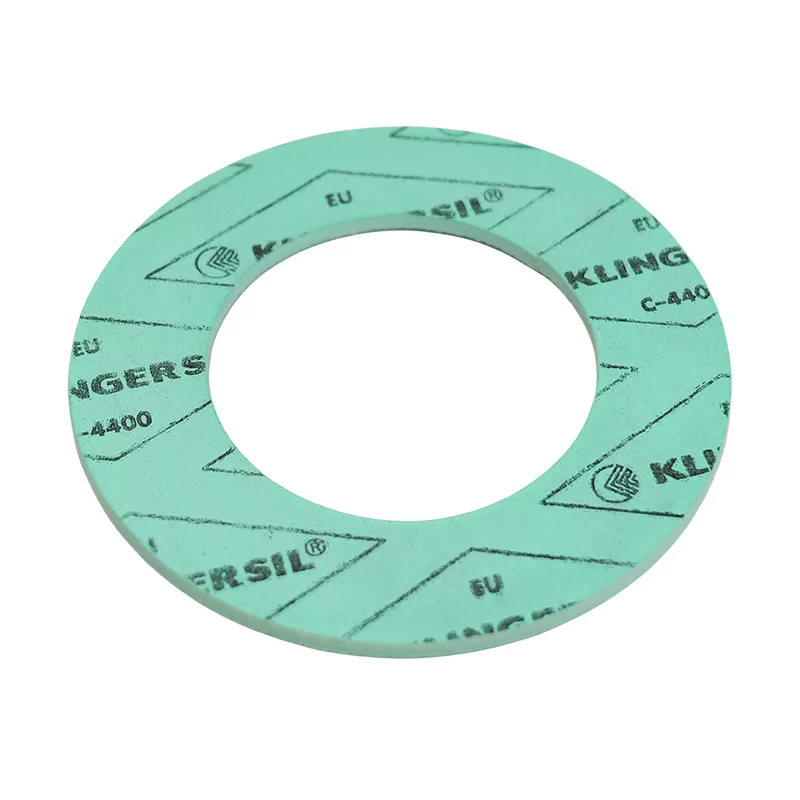

In the sophisticated world of industrial sealing, few materials have earned as much respect as flexible graphite. Known for its exceptional thermal stability and chemical resistance, graphite is the go-to solution for demanding environments. However, in its pure, unsupported form, graphite lacks the mechanical "backbone" required to withstand the crushing forces and high internal pressures of modern steam systems, refineries, and chemical plants. This is where the Reinforced Graphite Gasket becomes essential.

The Anatomy of Reinforcement

A reinforced graphite gasket is a multi-layered sandwich. The core is a thin metal insert—typically stainless steel—which acts as the skeleton. The graphite is then mechanically or chemically bonded to both sides of this insert. The choice of reinforcement is not arbitrary; it determines how the gasket will behave under high-pressure loads.

1. Tanged (Perforated) Metal Core

The most common reinforcement for high-pressure service is the tanged metal core. Small prongs or "tangs" are punched through a metal sheet (usually 0.1mm to 0.12mm thick). These prongs embed themselves into the graphite layers on either side.

Mechanical Grip: This creates a powerful mechanical bond that prevents the graphite from "extruding" or blowing out when the internal pressure of the pipe spikes.

High Pressure Resistance: Because the graphite is physically locked in place, tanged gaskets can handle significantly higher pressures than unsupported sheets.

2. Foil (Flat) Insert

In some applications, a flat metal foil is used instead of a perforated one. These layers are usually bonded with high-temperature adhesives. While foil-reinforced gaskets offer excellent sealability, they generally have lower "blow-out" resistance than tanged versions, making them better suited for high-temperature but moderate-pressure scenarios.

Why Graphite for High Pressure?

To understand why reinforced graphite is favored, one must look at its behavior under compression. Unlike elastomers (rubbers) which can degrade or "set," or PTFE which can "creep" (flow like a slow liquid under pressure), flexible graphite exhibits unique characteristics:

Micro-Conformability: Even under high pressure, the graphite remains soft enough to flow into the microscopic imperfections and scratches on a flange face. This creates a gas-tight seal at lower bolt loads compared to solid metal gaskets.

Incompressibility of the Mineral: While the gasket compresses to seal, the graphite flakes themselves do not lose their volume. This ensures that the gasket maintains a constant stress level against the flange.

Thermal Conductivity: Graphite dissipates heat away from the seal face, reducing the risk of localized "hot spots" that could lead to bolt relaxation and subsequent leaks.

Performance in Extreme Conditions

High-pressure applications are rarely just about pressure; they almost always involve extreme temperatures and aggressive chemicals. Reinforced graphite gaskets thrive in this "triple threat" environment.

Thermal Stability

Pure graphite can withstand temperatures up to 450°C (850°F) in oxidizing atmospheres and over 2,500°C in inert or reducing environments. In high-pressure steam service—where pressures can exceed 100 bar—the graphite remains stable. Unlike compressed non-asbestos sheets (CNAF), which rely on rubber binders that eventually harden and crack, graphite contains no binders. It does not become brittle over time.

Chemical Inertia

High-pressure chemical reactors often handle corrosive media. Graphite is chemically inert to almost all organic and inorganic biocides, acids, and alkalis (with the exception of strong oxidizing acids like concentrated nitric or sulfuric acid). This makes it a universal choice for multi-purpose plants.

The Danger of Blow-Out and the "Reinforcement" Solution

In high-pressure piping, the greatest fear for a maintenance engineer is a "blow-out." This occurs when the internal pressure of the fluid overcomes the friction and structural strength of the gasket, physically forcing a piece of the gasket out of the flange gap.

In an unsupported graphite gasket, the material is relatively weak in tension. High pressure can simply "tear" through the graphite. The metal reinforcement changes the physics of the joint. The metal core provides tensile strength, while the tanged prongs create a high-friction interface that "pins" the graphite in place. This allows reinforced graphite gaskets to be used safely in Class 300 and Class 600 pressure ratings, and in some cases, even higher.

Handling and Installation: The "Soft-Touch" Requirement

Despite their high-pressure capabilities, reinforced graphite gaskets are surprisingly delicate before they are installed.

Surface Sensitivity: The graphite surface is soft. A stray fingernail or a tool dropped on the gasket can create a deep scratch. While graphite is "self-healing" to an extent under compression, deep gouges can create leak paths.

The "Metal Edge" Risk: When cutting reinforced graphite, the metal core can create sharp edges. Proper handling with gloves is essential, not just for safety, but to ensure the edges aren't bent, which would prevent the gasket from sitting flat on the flange.

Torque Accuracy: Because graphite is so efficient at sealing, there is a temptation to under-torque the bolts. However, for high-pressure service, reaching the "seating stress" is critical. The reinforcement requires a certain amount of load to fully engage the tangs and compress the graphite into the metal's texture.

Variations: The Evolution of Graphite Seals

To further enhance the performance of reinforced graphite in high-pressure steam and oxidation-prone environments, manufacturers have introduced several specialized variations:

Oxidation Inhibitors: Grade "A" graphite is often treated with phosphorus-based inhibitors. This slows down the rate at which the graphite reacts with oxygen at high temperatures, extending the gasket's life in high-pressure air or steam systems.

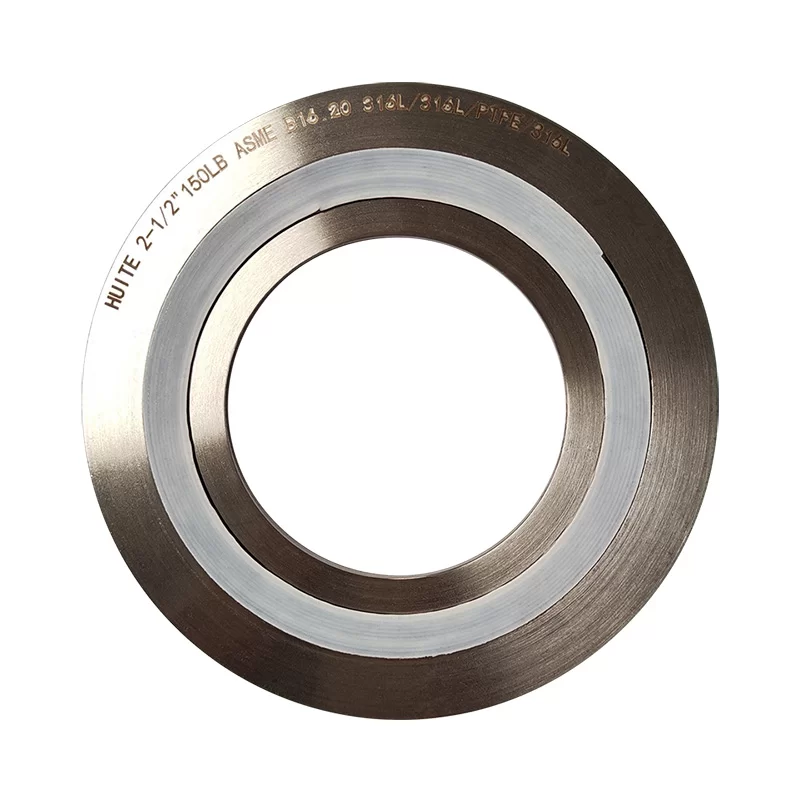

Stainless Steel Inner Eyelets: For the most extreme high-pressure applications, a reinforced graphite gasket can be fitted with a "U-shaped" metal border on the inner diameter. This eyelet protects the graphite edge from direct fluid erosion and provides an extra layer of blow-out protection. It also prevents the graphite from contaminating the process fluid.

The Reliable Workhorse

The reinforced graphite gasket is a testament to the power of composite materials. By taking the natural sealing brilliance of graphite and anchoring it to a steel heart, industry has found a solution that bridges the gap between soft elastomers and hard metal gaskets.

Whether it is in the high-pressure steam lines of a power plant or the volatile hydrocarbon lines of a refinery, these gaskets provide a level of security that pure materials simply cannot match. They offer the "forgiveness" needed for older, slightly warped flanges, while providing the "strength" needed to contain the immense energies of modern industrial processes.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.